Call them:

+49 2831 – 395 959 50

PEERENERGY

Stay up to date !

Category:

Search here:

Pulsed Plasma Nitrocarburizing (PPNC) with Post-Oxidation for 42CrMo4 / 50CrMo4 Gun Barrels: Precision, Durability, and Performance

In the demanding field of firearm manufacturing, barrel performance and longevity are of central importance. An advanced solution that is gaining increasing relevance—particularly for barrels made of 42CrMo4 / 50CrMo4…

Enhancing Powder Dehydrogenation and Component Quality with FAST Technique !

The Field Assisted Sintering Technique (FAST), also known as Spark Plasma Sintering (SPS), is revolutionizing titanium powder processing.

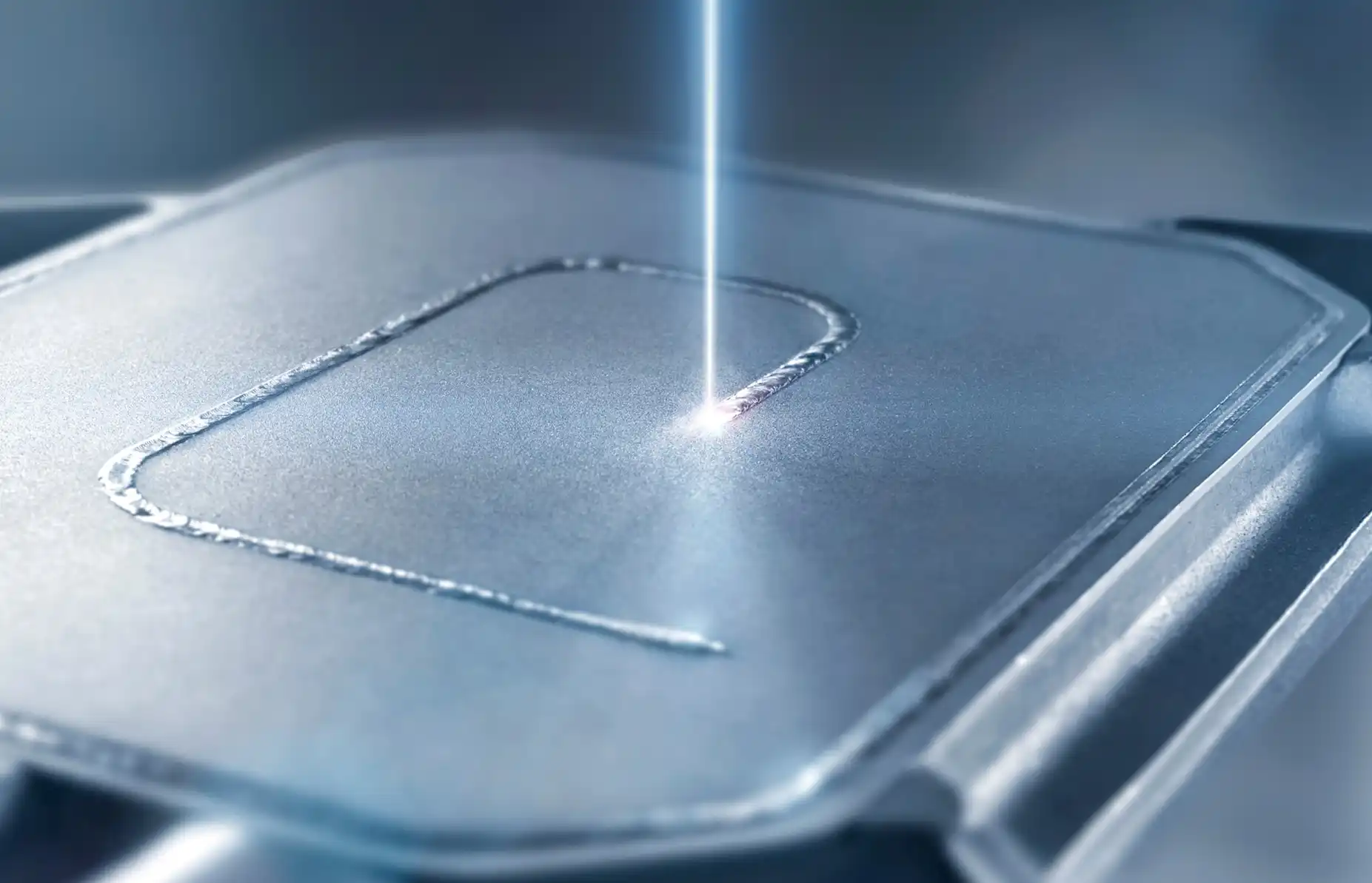

Electron Beam Welding for Rigid and Thick-Walled 5083 Aluminum Structures in Semiconductor Machinery

Semiconductor production machinery often requires high-strength, corrosion-resistant aluminum structures with excellent durability and dimensional stability. 5083 aluminum alloy, part of the 5000 series (Al-Mg), is a widely used material due to its exceptional corrosion…

Optimized Furnace Design for Debinding and Sintering of Titanium Alloys

Debinding and sintering are critical steps in the powder metallurgy of titanium alloys, particularly for applications in medical and aerospace industries, where stringent purity and mechanical performance requirements must be met.

Hot Isostatic Pressing (HIP) for Titanium Alloys: Strategies to Minimize Oxygen Exposure

Hot Isostatic Pressing (HIP) is a critical process for producing dense, defect-free titanium alloy components with enhanced mechanical properties. This process is especially vital for high-performance applications, such as in…

FAST Sintering of Ti-6Al-4V Components

FAST sintering revolutionizes the production of Ti-6Al-4V components through rapid and efficient densification. This technology enables high-strength, precise parts for aerospace, medical, and automotive industries. Despite geometric limitations, it offers…