Spares

We supply high-performance heaters, helical heaters and meander heating elements in different versions for different temperatures. All our heaters are characterized by high and constant quality and thus guarantee for good temperature uniformity over their complete long service life.

Meander Heating Elements up to 1400°C made of strip material

Custom made heaters for different furnace types, such as: air-circulation chamber furnaces, boogie hearth furnaces, hood furnaces, etc.

- Operation temperature up to maximum 1400°C

- Strip thickness from 0.1 to 4.0 mm

- Strip width from 4.0 to 200 mm

- Constant performance (temperature uniformity) over the entire service life

MoSi₂ High Performance Heating Elements up to 1800°C

- Standard in straight or bended version

- Various shapes and sizes on enquiry

- Constant performance (temperature uniformity) over the entire service life

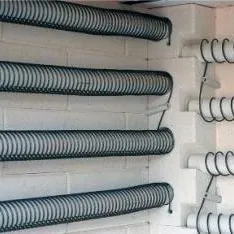

Helical Heaters up to 1400°C made of wire

Custom made heatingers for different furnace types such as: air-circulation chamber furnaces, boogie hearth furnaces, hood furnaces, etc.

- For directly or indirectly heated furnaces

- Wire diameter from 1.0 to 4.25 mm

- Constant performance (temperature uniformity) over the entire service life

To realise a free heat radiation, helical heaters come usually mounted on ceramic supporting tubes. Alternatively the heaters can be laid in groove stones (i.e. slots in the furnace walls) and are thus subject to better protection against mechanical impacts while loading and unloading the furnace. In connection with indirectly heated furnaces (e.g. laboratory furnaces) the heaters can be mounted in ceramic plates.

We are looking forward to your enquiry. In connection with larger and more complex replacements we look also forward to consulting you.