Fast Direct Hot Pressing

FAST stands for “Field Assisted Sintering Technique”. The mold is directly connected to electric power. The resistivity of the mold material and the powder part or green compact generate the heat directly inside the mold. Not the furnace, nor the atmosphere inside the furnace are heated up. The heat is only generated where it is needed.

Example of a FAST furnace:

Main advantages compared to traditional sintering methods are:

- Very little or no grain growth

- Improved microstructure, thus enhanced product performance

- Higher productivity

- Lower energy consumption

- High production flexibility

In order to get to uniform and repeatable quaity of high performing break pads, the chosen sintering process must also be of high performance.

Also the auxiliary equipment for granule preparation must be well performing, in order to achieve the applications’ demanding brake pad properties.

Auxiliary equipment

Mixing Powders

Especially for R&D and small-scale production, Dr. Fritsch produces two types of mixers which produce a homogeneous mix of typical friction material bonds. Examples of powder mixers:

Granulation

Some brake manufacturers have studied using granulated powder and report that granulating the powder mixture before cold-pressing delivers even better brake performance results. A granulation process creates powder agglomerations. Especially when using very inhomogeneous powders the components are distributed more homogenously when being granulated. Further advantages:

- Prevention of de-mixing, e.g. during transportation

- Improved flowability

- More homogeneous filling of cold-press cavities

Granulating the powder is not a mandatory process. However, it may give a competitive advantage when two products are directly compared with each other. Exmaples of granutatiom machines:

The advantages of the FAST Hot-Pressing process

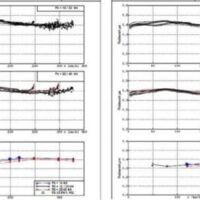

The graph below shows a comparison between train brake pads which have been sintered with a conventional bell furnace and the same type of brake pads which have been sintered with a FAST Hot-Press. The curves show the result of a dynamometer test run. Each line stands for a single brake pad.

The upper graph shows the dynamometer test at a braking force of 33 kN, the middle graph at 45 kN. The performance has been tested at speeds up to 330 km/h.

The higher the speed gets, the more obvious is the difference between the two sinter techniques . Especially at high braking forces and high speed, the brake pads sintered with a FAST Direct Hot-Press show a significantly better braking performance compared to brake pads sintered in a traditional furnace.

The main reason for this is the very much reduced grain growth, in connection with the much more advanced control of the process parameters like temperature, pressure and time.

We work with you to analyze your process and capacity requirements and plan for you the furnace solution that best meets your component property and geometry needs as well as your material work-flow.