We work with you to analyse your process and capacity requirements and select the furnace solution that best meets your component geometry needs and material production flow.

Harden & Temper and Case Hardening Lines

Case harden & tempering of small components made of low alloyed steels usually requires quenching in oil combined with a very short „quench delay time“ and enhanced quench power, in order to ensure uniform transformation into martensite throughout the workpiece. The SYSTEM 250 meets all of this requirements and is thus an ideal solution to harden and temper small components such as MIM parts and fasteners.

The SYSTEM 250’s unique selling proposition is the movement of the austenized or carburized workpieces into the oil-quench bath without exposure to air atmosphere and within shortest possible time (< 8s). The short „quench delay time“ can only become realized with vertical arranged furnaces! This is the reason why the SYSTEM 250 suits so well to heat treatment of small components, such as: MIM parts, fasteners or other small components in the armament, aerospace, automotive and machinery industry.

t’s modularity makes it very easy to compose furnace lines for different processes and different quench media. For instance: quenching is salt (austemper processes) or quenching first in salt to martensite temperature +50K, then temperature equalization and after that quenching in water.

The austenizing/carburizing furnace can run with different carrier gases, such as: Endogas or Nitrogen/Methanol. The C-level control takes usually place by means of an enrichment gas, such as: natural gas or propane.

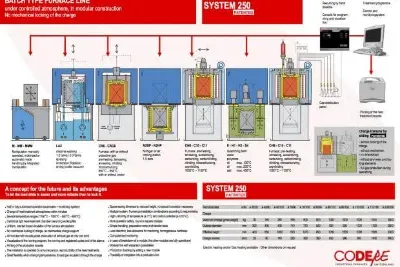

Typical line composition:

Click here to download brochure

All systems can be delivered with AMS 2750 E or CQI-9-HTSA compliance to meet the high standards and requirements of aerospace and first tier automotive industries. Since the line operates workpieces batch-wise, traceability is 100% ensured!

The two most common processes the equipment is used for, are: Harden and Temper and Case Hardening (Carburizing or Carbo-nitriding).

A few examples of typical workpieces:

Aeropace industry

Also landing gears are made of materials requiring short „quench delay times“, in order to achieve uniform material properties, little distortion and little surface reaction with air-atmosphere.

The shortest possible quench delay times can be achieved with vertically arranged furnaces.