We work with you to analyze your process and capacity requirements and select the furnace solution that best meets your component geometry needs and material production flow.

The selection of the system basically depends on the process required, the component geometry and the component quantity. As a rule we always have a furnace in production that can be used to carry out tests on your component samples. Please understand that we cannot carry out these trials free of charge.

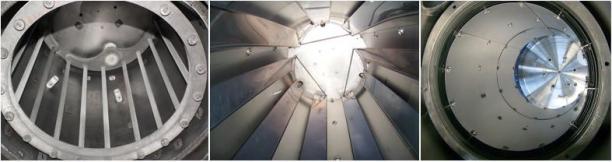

Sinter furnaces in robust vertical design

For the manufacture of products made from high purity metals and metal alloys, PIM, MIM & CIM, non-oxide ceramics, cermets, rare earths, fine chemicals, carbon chemistry and for refinery by Heat Treatment. The modular vacuum- and protective-gas furnace systems are designed to provide a system to the user, that can operate with different thermal insulation- and heating elements. Within a short time period (approx. 2h) the user can change the insides (thermal insulation and heating elements) of the vacuum-tight, double-wall and water-cooled stainless-steel furnace body completely. This enables the user to extend the capabilities of his furnace even after a few years with a minimum of financial investments.

Advantages at a glance:

- Simple and user friendly operation via touch panel

- High reliability, thus little need for repair

- Minimal footprint, due to a steel frame with integrated peripherals,such as: gas supply, cooling water distribution and transformer

- Decentral control components

- Double-walled water-cooled stainless steel jacket with two major openings (bottom-flange for loading and unloading; top-flange for service)

- Different hot-zone types with single zone controlled circumferentially oriented heaters (graphite, molybdenum, tungsten, MoSi2 with ceramic fibre insulation – depending on type of process atmosphere)

- Mechanically unencumbered freely suspended heating elements for a long service life

- Cylindrical working chamber circumferentially heated (Ø x H) to achieve excellent temperature uniformity; temperature uniformity ≤ 5 K according to DIN 17052-1 and AMS 2750 E

- Elevator for loading and unloading (electrically driven bottom-flange„bottom loader“) for easy and fatigue-free load preparation

- Horizontal design for loading and unloading from the front on request

- Two independent temperature measurement points (furnace control / over-temperature monitoring)

- Easiest transport in two packages (furnace and control cabinet) hence fast assembly and disassembly

- Our furnaces fulfill the highest requirements for a clean sintering process and are thus the ideal solution for sintering of components typically used in the medical industry and in the aerospace industry (e.g. titanium components).

- Furnaces enable debinding and sintering in the sweeping gas partial pressure. The following gases can be used in partial pressure: N2, Ar and also H2.

- The sweeping gas is thus passed over the components and “transports away” all the residual contaminants from the components.

- Contaminated process gases can, for instance, become passed through a thermal post combustion unit out of the furnace. In this way the time consuming and unhealthy cleaning of condensation traps is resolved ensuring greater furnace availability compared to furnaces with condensation traps.

Examples of application:

In the manufacture of MIM (Metal Injection Molding) components, debinding is carried out first. Different processes are employed. Debinding of extruded parts is frequently effected at first in water or solvents. The type and residue of the binder in the component as well as the type of metallic materials determine the furnace solution used for thermal residual debinding and sintering. In the case of very large quantities of residual binder (as a rule these are polymers) it is recommended to always employ thermal pre-debinding and, if required, pre-sintering outside of the high temperature sintering furnaces in order to prevent contamination so that the high temperature sintering furnace remains clean. In the case of catalytic debinding, sintering is effected in the vertical thermal debinding/sintering furnace, as the residual binder quantity is low, and the components need not be moved longer.

Typical materials that find application as MIM components are:

- Low alloyed steels for heat treatment

- Stainless steels and ultra heat resistant steels

- Tool steels

- Soft magnetic steels

- Special alloys

- Titanium

A solution tailored, for example, to the BASF Feedstock is the combination of a catalytic debinding furnace followed by residual debinding and sintering in a vacuum sintering furnace. We have detailed the combination of a catalytic debinding furnace and a residual debinding & sintering furnace here only as a possible solution.

Hard metals can be basically divided according to the following alloy types: WC-Co hard metal, WC-(Ti,Ta,Nb) C-Co hard metal, cermets (hard metal containing high levels of titanium carbide) and special carbides. Typical applications are, for example: machine tools, non-chip producing processes (drawing dies, die plates, rolling etc.). Wearing parts like bearings, sealing rings, plunger, grinding spindle, equipping in reduction devices, pressing tools and much, much more. As a rule the carbide components undergo debinding and pre-sintering after pressing (green parts) in a debinding/pre-sintering furnace in order to again, if necessary, process the brown parts mechanically before the high temperature sintering stage. The sintering process employed depends on the required density of the carbide components. Hot Isostatic Pressing (HIP) is employed for carbide components of the highest density and for the great remainder of carbide metals high temperature sintering in inert gas at low atmospheric pressure or high temperature sintering in a vacuum. The sintering temperatures usually range from 350 °C – 1500 °C. For customers who employ a process with partial pressure debinding the furnace can also be fitted with a partial pressure system for the infinitely variable adjustment from 1 to 1000 mbar. We recommend debinding and sintering under inert gas atmospheric conditions or reactive gas atmosphere under slight atmospheric overpressure with thermal post combustion of the binder. This is the fastest and cleanest process for the manufacture of cemented carbides of a consistent high quality!

For thermal debinding and pre-sintering we may offer you our metallic Retorte furnace with the following design features:

- Metallic hot zone

- Two-zone heating

- Temperature uniformity within the retort +/- 5K in the range 350 °C – 900 °C

- Nitrogen sweeping gas

- Thermal post-combustion unit to burn off the binder

- Fully automatic operation

- Nitrogen sweeping gas

- Thermal post-combustion unit to burn off the binder

- Fully automatic operation

Carbonising, Graphitising & Siliconizing in High Temperature Furnaces Our high temperature furnaces are mainly utilised to manufacture CFC parts, graphite components, graphite fibres and silicon carbide components. Components from these materials currently find application predominantly in the furnace construction industry and in the aerospace industry. Due to the interesting material properties such as light-weight construction paired with high strength or extremely high load-carrying capacity in very high temperatures in oxygen-free atmosphere, components made of the above-mentioned materials are increasingly in demand. To manufacture graphite components of the highest purity, temperatures over 2800 °C are required. Alternatively, the highest level of purity can also be achieved with temperatures of 2000 °C upwards if used in combination with a cleaning gas. We supply laboratory and production furnaces for the manufacture of carbon-based materials. We work with you to analyze your process and capacity requirements and select the furnace solution that best meets your component geometry needs and material production flow. The selection of the system basically depends on the process required, the component geometry and the component quantity. As a rule we always have a furnace in production that can be used to carry out tests on your component samples. Please understand that we cannot carry out these trials free of charge.