Sinter Furnaces in Robust Vertical Design

High-temperature sintering furnaces for thermal debinding and sintering of technical oxide ceramics

For the manufacture of products made from high purity metals and metal alloys, PIM, MIM & CIM, non-oxide ceramics, cermets, rare earths, fine chemicals, carbon chemistry and for refinery by Heat Treatment. Our modular vacuum- and protective-gas furnaces are designed to provide a system to the user, that can operate with different thermal insulation- and heating elements.

Air Atmosphere Sinter Furnaces

High temperature debind and sinter furnaces for thermal debinding and sintering of technical oxide-ceramics

Debinding and sintering of technical oxide ceramics usually takes place in air atmosphere. For the debinding processes (debinding of green parts) most manufacturers use accordingly modified chamber furnaces with an efficient air circulation system for high temperature uniformity and a catalytic or thermal converter for waste gas cleaning. Subsequently the parts (brown parts) are sintered at up to 1800°C in a separate high temperature furnace

Hot Presses and Spark Plasma Sintering Technology

Field Assisted Sintering Technology (FAST/SPS) and FAST/Hybrid sintering systems

Components made for very harsh environments require very special processes to make them. With sintering equipment such as “Hot Presses” or “Spark Plasma Sintering Machines” components with high-end material properties required to meet demanding applications can become manufacture.

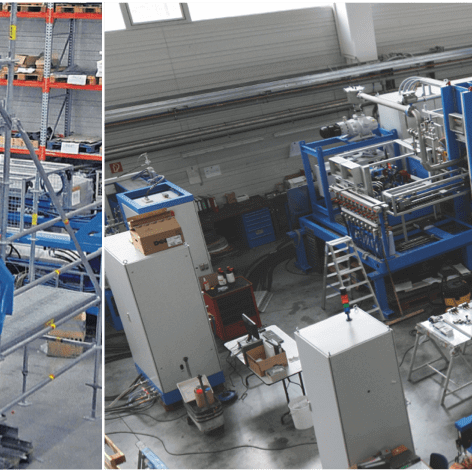

Fast Direct Hot Pressing

FAST Furnace with direct current for the production of friction linings

A unique FAST-heating sintering process developed by a German sintering pioneer has been becoming a new production standard in the friction material industry. Up to now, almost 1000 sinter presses have been installed worldwide. FAST stands for “Field Assisted Sintering Technique”. The mold is directly connected to electric power.